On July 14, 2025, Chongqing Chuke Intelligent Machinery Equipment Co., Ltd. (hereinafter referred to as "Chuke Intelligent") successfully completed a high-precision cutting and marking test task for a gem processing company in various countries with its leading UV laser technology, achieving a processing accuracy of ±0.001 mm, breaking the long-standing technical bottleneck in the field of gem processing in one fell swoop, and setting a new benchmark for the industry.

The customers of this cooperation are well-known gem processing companies in various countries, and their products are widely used in jewelry, precision instruments and

Other fields. Due to the high cost of gem materials and the great difficulty of processing, customers have put forward strict requirements on equipment accuracy, thermal impact control and processing stability: micron-level pattern cutting and marking must be achieved on the sapphire surface, and no thermal damage or cracks must be generated during the processing process.

However, in the early research, customers found that most of the more than 30 laser equipment manufacturers in various countries can only provide fiber, quasi-continuous or

Mopa Fiber Laser cutting solutions, but these technologies cannot meet the demanding needs of gem processing due to significant thermal effects and insufficient precision. After months of fruitless searching, the customer placed their hopes on Chuke Intelligent.

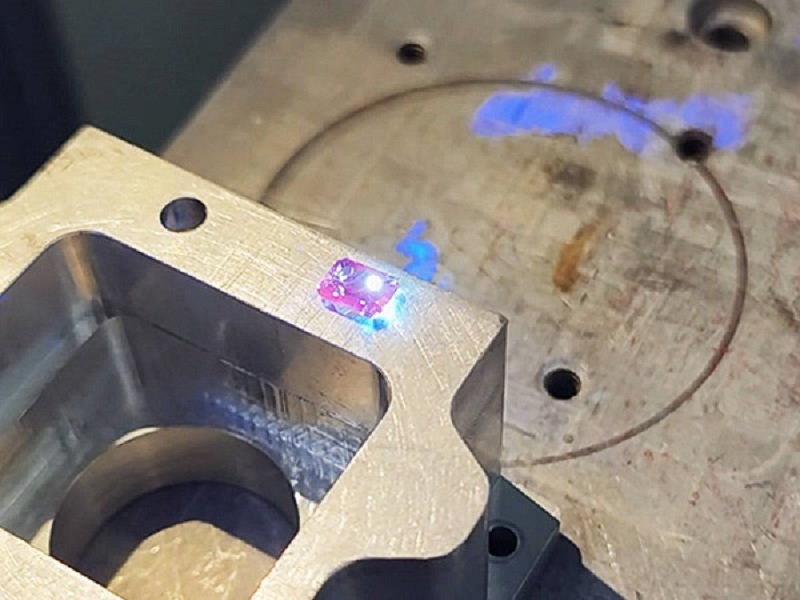

As an innovative pioneer in the field of domestic laser precision processing, Chuke Intelligent first proposed the use of a 30W

UV Laser Marking Machine for gem cutting and marking tests. Unlike traditional laser technology, UV lasers have the characteristics of short wavelength, high photon energy, and non-thermal melting. They can achieve material removal through "photochemical reaction" rather than thermal melting ablation, thereby completely avoiding the generation of heat-affected zones (HAZ) and ensuring zero damage to the gem surface.

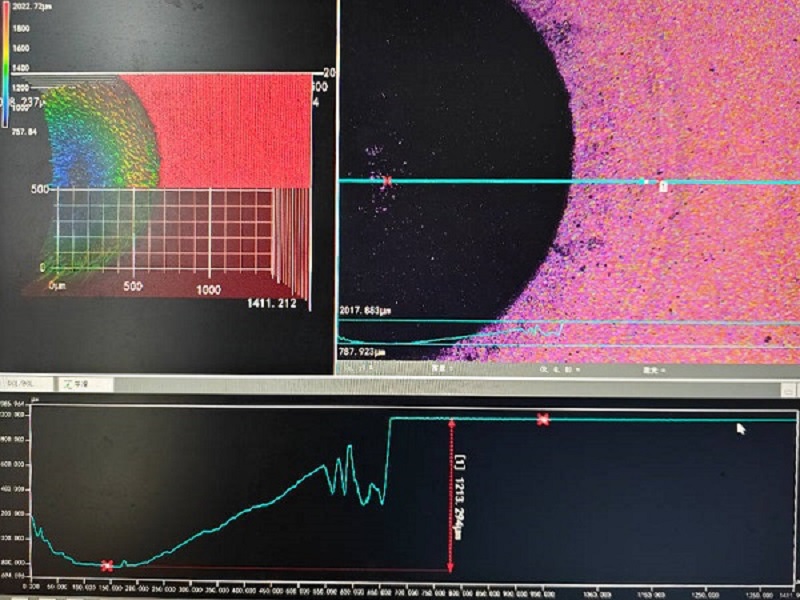

During the test, the Chuke Intelligent technical team optimized the laser pulse width, frequency, and scanning path based on the physical properties of sapphire, and successfully engraved complex patterns on the samples provided by the customer. After high-precision microscope testing, the processing error was controlled within ±0.001 mm, far exceeding customer expectations. During the acceptance, the customer representative exclaimed: "Chuke Intelligent's equipment not only solved our technical problems, but also redefined the possibilities of gem processing!"

This cooperation marks the entry of UV laser technology into the practical stage in the field of hard and brittle material processing. Xiao Renmin, Chairman of Chuke Intelligence, said: "Traditional laser equipment is often 'willing but insufficient' in gemstone processing, and the 'cold processing' characteristics of ultraviolet lasers just fill this gap. Our technology can not only be applied to sapphires, but also be extended to high-value materials such as diamonds, rubies, and ceramics, providing key support for manufacturing fields such as semiconductors and aerospace." In addition, Chuke Intelligence has applied for a number of patents around ultraviolet laser technology, and established joint laboratories with a number of scientific research institutions, continuing to delve into cutting-edge directions such as ultrafast lasers and multi-wavelength composite processing. This breakthrough has also attracted attention from the laser industry, and many foreign trade companies have expressed their intention to cooperate in technology.