On January 5, 2026, Chongqing Chuke Intelligent Machinery Equipment Co., Ltd. (hereinafter referred to as "Chuke Intelligent") achieved a major breakthrough in the field of bridge maintenance with its independently developed pulsed

Laser Cleaning Machine, successfully applied to the steel structure rust removal projects of several large-scale bridges in China. This innovative technology, with its precise, non-destructive, and environmentally friendly characteristics, is reshaping the traditional bridge maintenance model and providing key support for the industry's intelligent transformation.

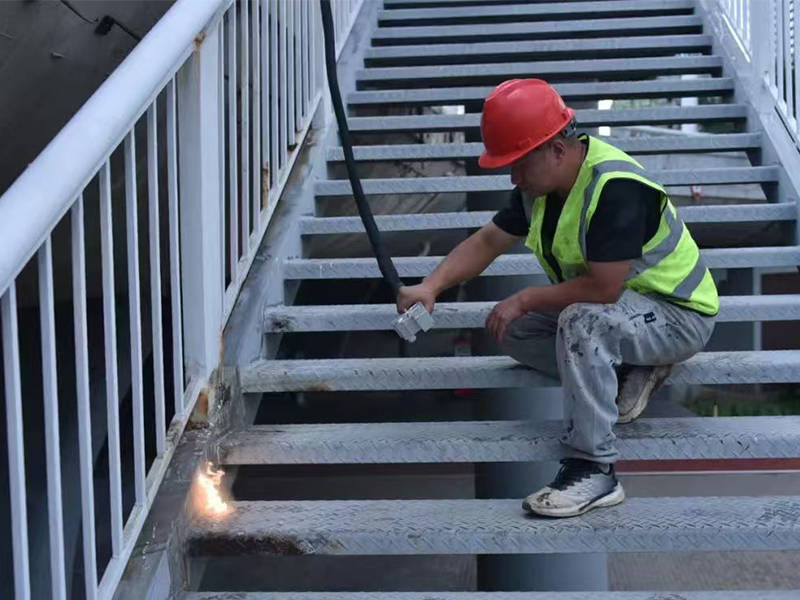

Traditional bridge steel structure rust removal relies on methods such as sandblasting and chemical cleaning, which suffer from drawbacks such as high dust pollution, difficulty in treating chemical waste, and damage to the substrate. Chuke Intelligent's pulsed laser

Cleaning Machine achieves precise separation of contaminants from the substrate through nanosecond-level high-energy laser pulses: the laser beam is absorbed by the paint or rust layer and instantly vaporized, while the metal substrate is perfectly preserved due to laser reflection.

“Our equipment can remove coatings or rust layers as thin as 0.01-2 millimeters with millimeter-level precision,” explained the Chief Technology Officer of Chuke Intelligent. In a maintenance project for a cross-river bridge, this technology completed the treatment of 2,000 square meters of rusted surface—a process that would have taken 15 days using traditional methods—in just 3 days. The cleaned metal surface also exhibited uniform roughness, providing excellent adhesion for new coatings.

Chuke Intelligent simultaneously launched a comprehensive solution encompassing “intelligent diagnosis +

Laser Cleaning + instant protection.” Before cleaning, an ultrasonic flaw detection system equipped with AI algorithms performs a 3D scan of the steel structure to accurately locate cracks, corrosion, and

Other potential hazards. After cleaning, the equipment automatically switches to a surface roughening mode to enhance the adhesion of the new coating. Finally, a robot applies the anti-rust primer, forming a closed loop of “detection-cleaning-protection.” “Traditional processes require multiple teams, are time-consuming, and are prone to secondary pollution. Our system can complete the entire process within a week, with no wastewater and no chemical residue,” revealed a project manager at Chuke Intelligent. In a project for a high-altitude bridge, this solution reduced maintenance costs by 40% and extended coating life to over 10 years.

Chuke Intelligent's pulsed laser cleaning machine has passed EU CE and US FDA environmental certifications. Its "dry cleaning" characteristic completely eliminates the dust diffusion and wastewater discharge problems associated with traditional processes. During the maintenance of an overpass in Chongqing, the equipment prevented a significant increase in surrounding PM2.5 concentrations and kept noise levels below 65 decibels, earning a "zero-complaint construction" rating from the municipal department. "We are currently collaborating with Southeast Asian countries to apply this technology to the maintenance of harbor bridges," said the Director of International Business at Chuke Intelligent. The equipment's remote monitoring system can transmit cleaning data to the cloud in real time, supporting multinational teams to collaboratively optimize parameters. Currently, Chuke Intelligent has established strategic partnerships with several central state-owned enterprises, and its equipment has been validated in numerous major projects across China, including bridges.

Based on its successful experience in bridge maintenance, Chuke Intelligent is developing specialized laser cleaning systems suitable for ship ballast tanks, nuclear power plant equipment, and historical building stone. "Our vision is to become a global leader in laser equipment," announced the General Manager of Chuke Intelligent at a recent technical exchange meeting. The company will upgrade to an "equipment + service + data" model, providing more customized solutions to global customers through its services.