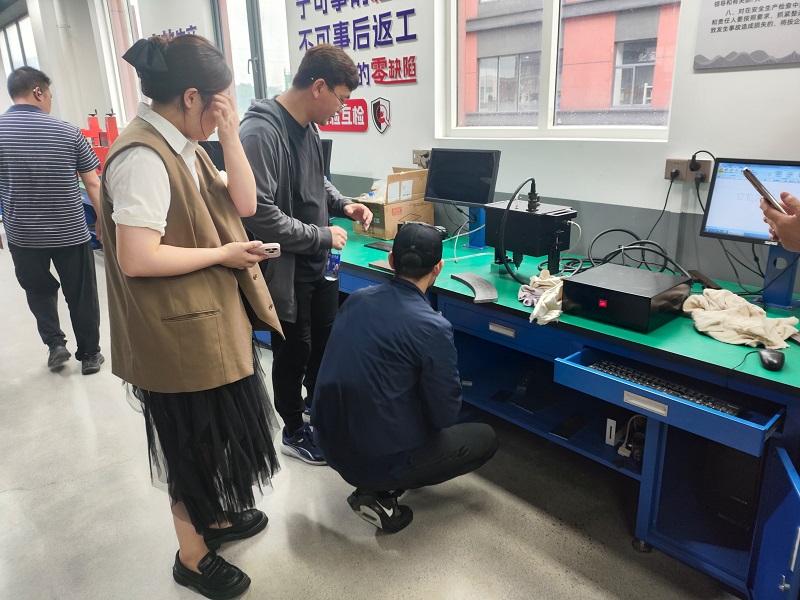

On September 12, 2025, Chongqing Chuke Intelligent Machinery Equipment Co., Ltd. (hereinafter referred to as "Chuke Intelligent") welcomed a Russian rail transit equipment purchaser. After multiple rounds of technical comparisons and on-site inspections, the customer flew to the Chongqing Chuke Intelligent factory to witness the on-site testing of Chuke Intelligent's customized train track deep marking solution. Ultimately, Chuke Intelligent impressed the customer with its exceptional performance of 0.8mm deep marking, and the million-dollar purchase order was signed on the spot, marking another victory for China's high-end marking equipment in the international rail transit sector.

As the core component that supports train operations, train track markings must meet stringent requirements such as high wear resistance, corrosion resistance, and long-term traceability. According to the International Union of Railways (UIC) standards, track surface markings must be at least 0.7mm deep to ensure legibility despite long-term friction and extreme conditions. However, this technological barrier has long plagued the global marking equipment industry: traditional laser marking machines are prone to thermal deformation of metal, while mechanical scribing suffers from insufficient precision and low efficiency.

"We visited nearly every

Marking Machine manufacturer in China, but our test results consistently hovered between 0.5 and 0.6 mm, failing to meet railway safety regulations," Igor said at the testing site. A turning point came in early 2025, when, recommended by industry experts, he learned about Chuke Intelligent's independently developed "ultra-pulse cold processing technology." This technology, by optimizing laser wavelength and energy density, achieves deep etching of metal microstructures while keeping the heat-affected zone to less than 0.1 mm, completely resolving the "depth, precision, and stability" dilemma in rail marking.

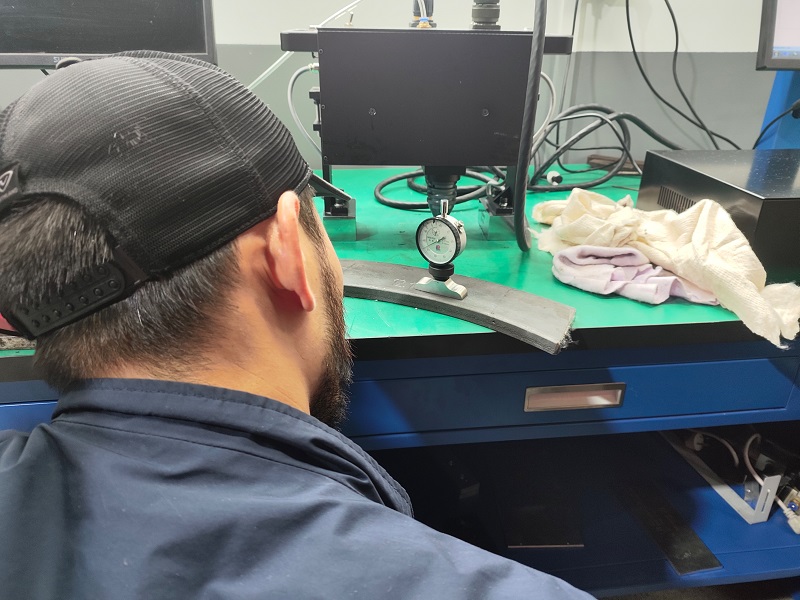

At Chuke Intelligent's intelligent factory in Chongqing's Liangjiang New District, Igor observed the entire testing process. Technicians secured a 500-kilogram section of U75V high-manganese steel rail to the test bench and activated Chuke Intelligent's latest generation FiberMark Pro series

Fiber Laser Marking Machine. As a green laser beam precisely traverses the metal surface, a clear mark measuring 0.82mm deep appears in just 30 seconds. Professional testing confirmed the mark's smooth, burr-free edges, with a depth tolerance within ±0.02mm, exceeding customer expectations.

"This is a true work of art!" the customer exclaimed, unable to conceal his excitement as he leaned over to touch the mark. "Chuke Intelligent not only meets the 0.7mm target, but also far surpasses similar European products in efficiency, energy consumption, and environmental friendliness." He revealed that the equipment will be used in a Russian railway modernization project, with procurement expected to exceed 100 million yuan over the next three years.

Xiao Renmin, General Manager of Chuke Intelligent, stated, "This collaboration demonstrates the transformation of China's equipment manufacturing industry from a 'follower' to a 'leader'." The company reportedly invests heavily in R&D annually and holds 87 patents. Its products serve over 20 heavy industrial sectors, including automotive, aviation, and energy, and are exported to 100 countries. This trans-Eurasian collaboration is adding a new dimension to global rail safety.