For daily industrial products and professional industrial products, in order to complete the necessary functions of product design and sales market, one or several metal surface treatment technologies and processing technologies must be adopted.

During the entire process of industrial product electroplating technology, phosphating treatment, coating, welding, packaging, and integrated route installation, it is necessary to remove surface plant oils, dust, rust, residual organic solvents, adhesives, and

Other waste to ensure the quality of the next technical process.

The current standards for

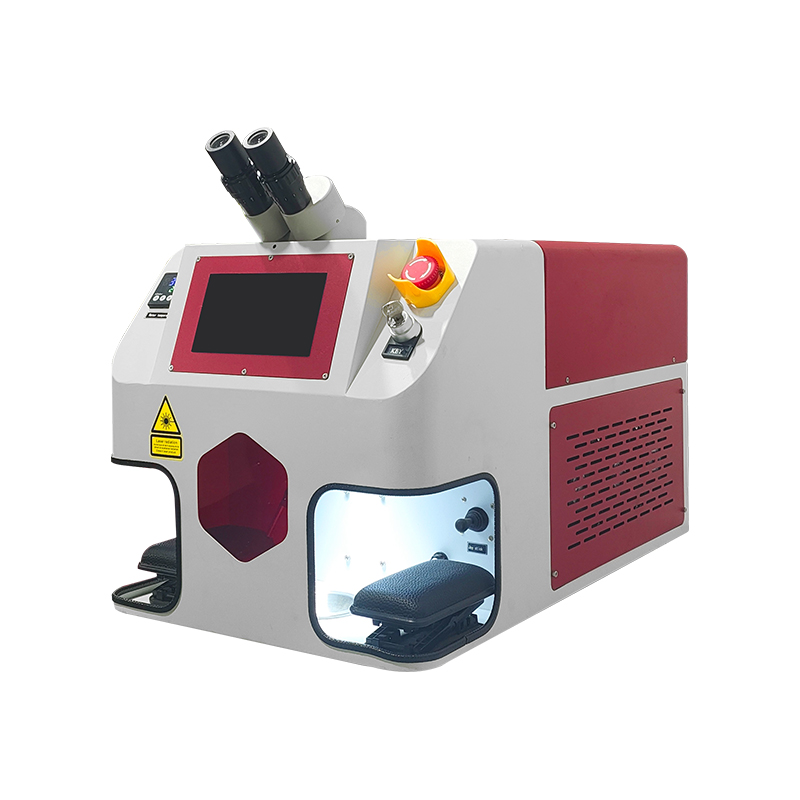

Yag Laser Jewelry Welder widely use cleaning methods in the field, including mechanical equipment cleaning, organic chemical cleaning, and ultrasonic cleaning. However, under the regulations of ecological environment protection and high-precision sales market, their application is greatly limited.

1.The mechanical equipment cannot meet the requirements for high cleanliness cleaning;

2.Organic chemical cleaning methods are very prone to causing air pollution, and the cleanliness obtained is also relatively limited; Especially when the composition of stains is complex, it is necessary to use a variety of cleaning agents for continuous cleaning in order to consider the requirements for surface cleanliness;

3.Although the ultrasonic cleaning method has a very good actual cleaning effect, it is powerless to clean submicron level dirt particles. The specifications of the cleaning tank limit the scope and complexity of the production and processing parts, and the dryness of the product workpiece after cleaning is also a major difficulty.