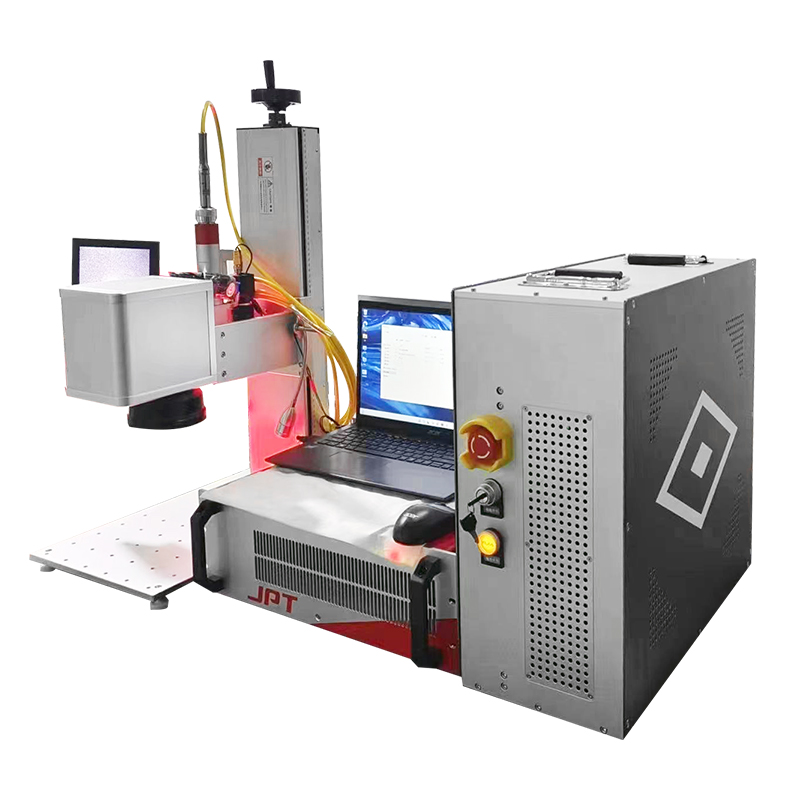

Laser Galvo Welder can achieve high-precision welding, with minimal heat damage and deformation, faster welding speeds, and smooth, aesthetically pleasing welds.

No post-weld treatment is required, and the weld quality is high, with no vents. Precise control is possible, the focal spot is small, and the precision level is high, making automation easy.

Depending on the solder material used in Laser

Galvo Welder, there are four main types of solder available: solder bars, solder paste, solder rings, and solder balls.

The key factor may be product characteristics. Most require three steps: spot heating, solder material heating, and molding heating. Therefore, the following parameters should be considered when choosing a solder material:

1. Select the solder material and welding method based on the product and production efficiency;

3. Based on the actual effect and efficiency, determine whether visual effects and temperature feedback are required;