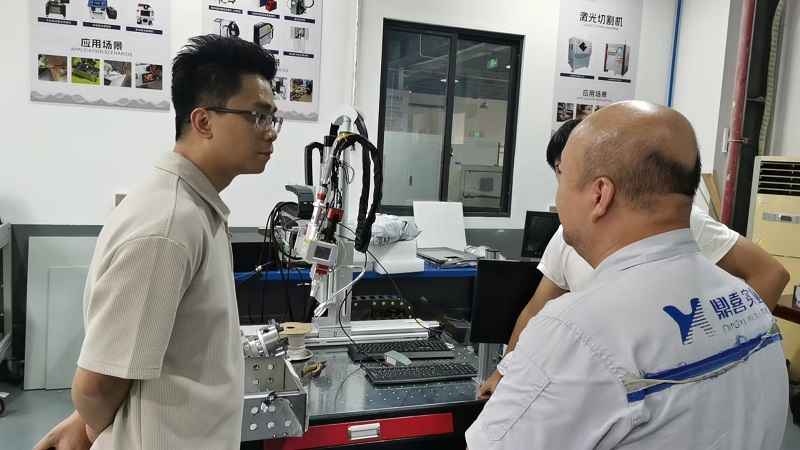

On September 29, 2025, Chongqing Chuke Intelligent Machinery Equipment Co., Ltd. (hereinafter referred to as "Chuke Intelligent") welcomed an air conditioner parts welding service provider. After inspecting the performance of Chuke Intelligent's high-power

Automatic Laser Welding Machine, the company representative highly praised its welding precision, efficiency, and stability, and expressed an intention to make in-depth purchases, marking a crucial step forward in the cooperation between the two parties in the field of high-end manufacturing equipment.

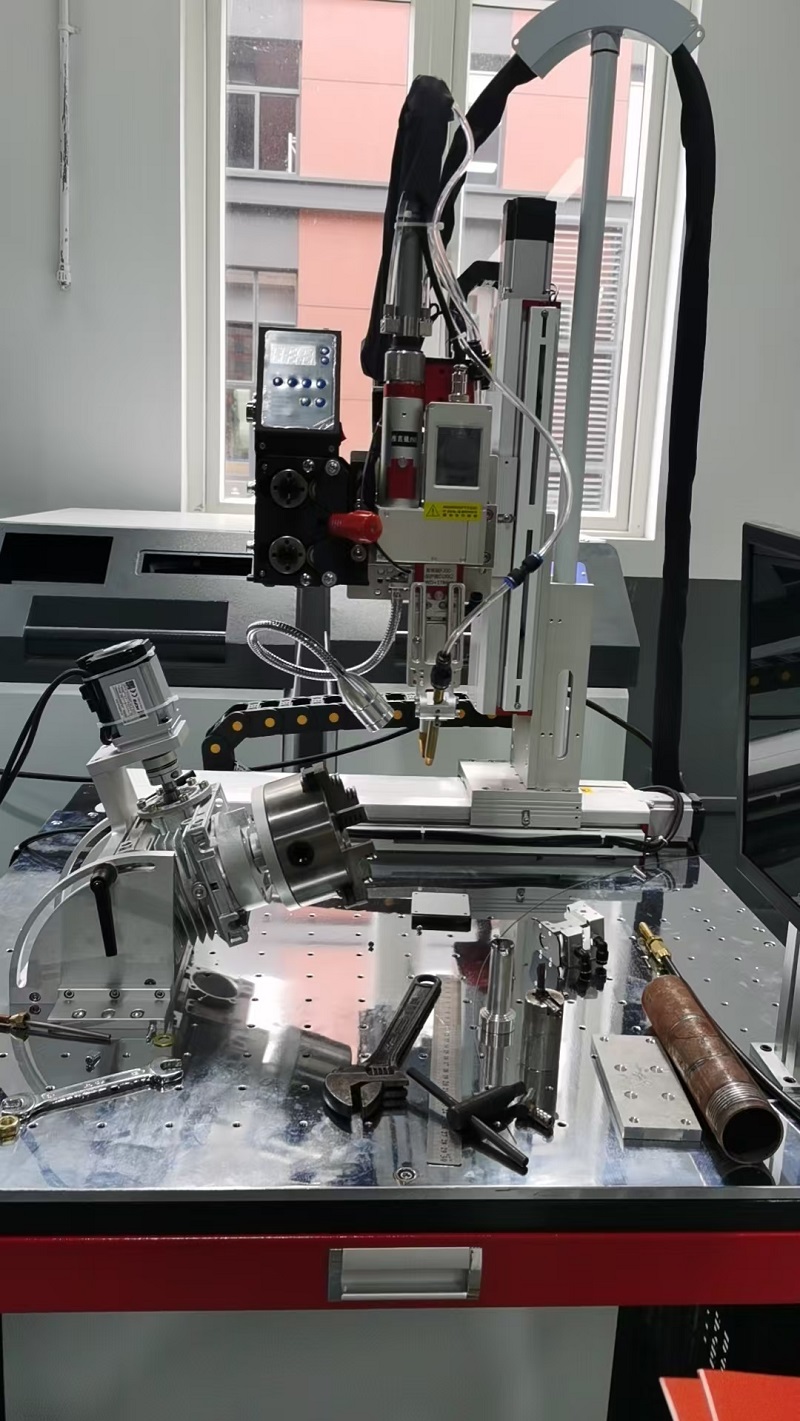

During this visit, the customer focused on testing the application of Chuke Intelligent's independently developed high-power fiber

Laser Welding Machine in the welding of air conditioner copper pipes, aluminum heat sinks, and other parts. The testing simulated actual production scenarios, including complex processes such as butt welding of 0.2mm thin copper pipes and lap welding of medium-thick copper connectors. The laser beam was precisely focused, resulting in a smooth and flat weld surface free of defects such as porosity and cracks, fully meeting the stringent requirements of the air conditioning industry for sealing and corrosion resistance. Compared to traditional argon arc welding, laser welding offers speeds more than three times faster, reducing single-piece welding time to within two seconds, and eliminating the need for subsequent grinding. By adjusting the beam mode and oscillation parameters, the equipment can flexibly handle welding requirements for different materials such as copper, aluminum, and stainless steel, solving the challenge of multi-material compatibility in air conditioning components.

A customer's technical manager stated, "Chuke Intelligent's equipment excels in heat-affected zone control and weld penetration consistency, making it particularly suitable for the air conditioning industry's welding needs for lightweight, high-thermal-conductivity components."

As a national high-tech enterprise, Chuke Intelligent has continuously invested in R&D in laser welding in recent years. Its high-power laser welding machine possesses three core advantages: Dynamic beam adjustment technology: Employing a ring-spot laser, precise control of weld penetration and spatter is achieved through beam mode switching, resulting in internationally leading welding stability. Intelligent monitoring system: Integrating multispectral sensors, it monitors weld temperature and weld pool morphology in real time, automatically correcting parameter deviations to ensure consistency in mass production. Modular design: The equipment supports six-axis robotic arm linkage, automatic wire feeding, and other functions, allowing for rapid adaptation to the flexible production needs of different production lines.

According to the technical director of Chuke Intelligent, the company has already customized and developed several specialized laser welding equipment for the automotive, aviation, and shipbuilding industries. This breakthrough in the air conditioning parts field further validates the versatility of its technology.

With the advancement of the "dual carbon" target, the air conditioning industry is accelerating its transformation towards high efficiency, energy saving, and lightweight design, placing higher demands on welding processes. Traditional welding methods, due to their high heat input and high deformation rate, are no longer sufficient to meet the sealing standards of new environmentally friendly refrigerant pipelines. Laser welding, with its non-contact, low heat-affected zone, and high precision characteristics, has become a key piece of equipment for industry upgrading.

"The performance of Chuke Intelligent's equipment completely exceeded expectations, especially its localized service team's ability to respond quickly to needs, which was a crucial factor in our choice to cooperate," the client stated. It is understood that the company plans to initially purchase 10 high-power laser welding machines for its newly built intelligent production line, which is expected to increase annual production capacity by 40% after commissioning.

Xiao Renmin, General Manager of Chuke Intelligent, stated, "The company will take this cooperation as an opportunity to further deepen its research on laser applications in new energy, smart home, and other fields, contributing to the transformation of Chinese manufacturing towards high-end and intelligent manufacturing."