Post-weld treatment is equally important, affecting not only the product's appearance but also its corrosion resistance and overall strength.

Traditional post-weld treatment methods, such as manual grinding and mechanical polishing, are time-consuming and labor-intensive, and can result in uneven weld surfaces, impacting the product's overall aesthetics.

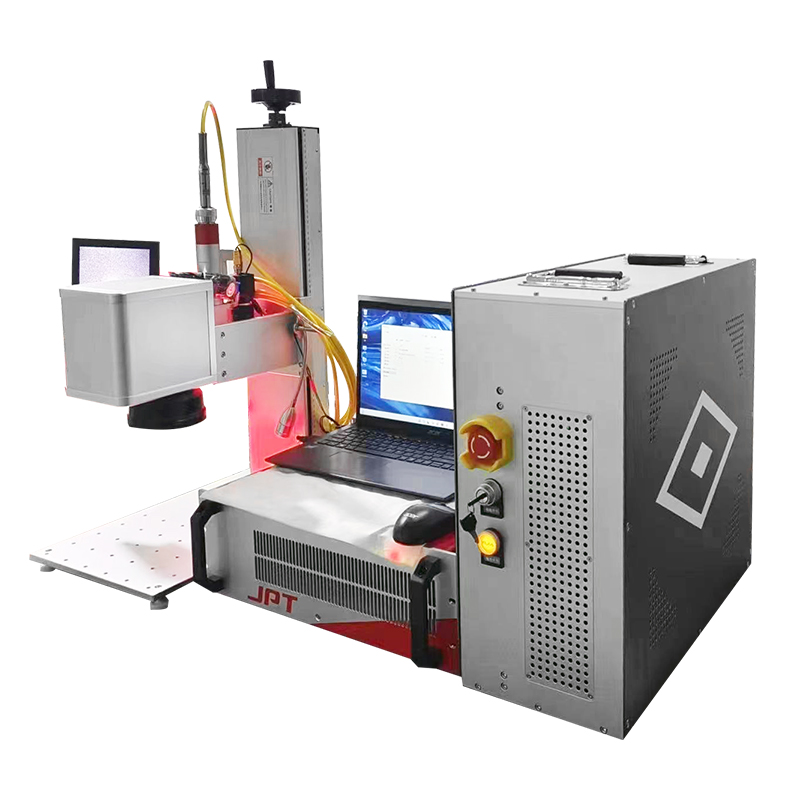

Laser Cleaning Machine, however, can efficiently and precisely remove spatter, scale, and slag from weld surfaces, leaving them smooth and clean.

Laser

Cleaning Machine utilize advanced laser technology to quickly remove impurities from weld surfaces without damaging the weld itself.

Furthermore, the portability of

Laser Cleaning Machine allows them to be used in various complex welding environments, easily handling both large structural components and small precision parts.

In today's increasingly stringent environmental regulations, the environmental advantages of Laser Cleaning Machine are particularly prominent.

Traditional pre- and post-weld treatment methods, such as chemical cleaning and manual grinding, often generate large amounts of wastewater and waste, polluting the environment.

Laser Cleaning Machine, on the

Other hand, generate no waste during the cleaning process, require no chemical reagents, and produce no wastewater discharge, meeting modern industrial environmental standards.