In modern industrial production, cleaning castings has always been a crucial step. Traditional manual grinding methods are not only inefficient but also prone to causing injury to operators.

Laser Cleaning technology, with its high efficiency, environmental friendliness, and precision, is revolutionizing casting cleaning.

Traditional manual grinding requires significant manpower and time, and the results are often inconsistent.

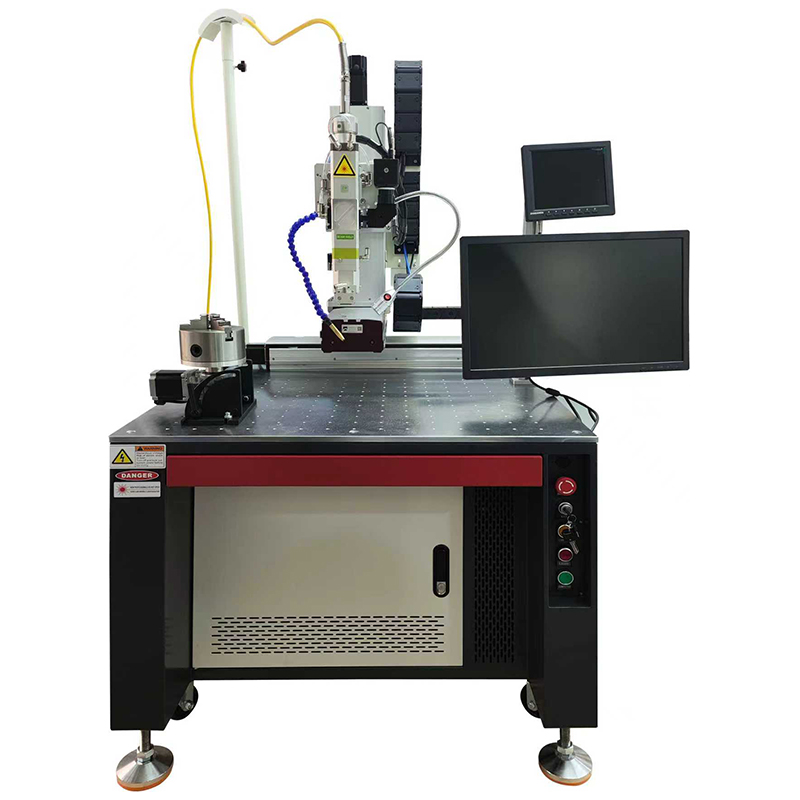

Laser Cleaning Machine, however, can efficiently remove rust and impurities from the surface of castings in a short time.

The high-energy laser beam can precisely target the rust, instantly peeling it off without causing any damage to the casting itself.

This highly efficient cleaning method significantly shortens the production cycle, improves enterprise production efficiency, and saves enterprises substantial time and costs.

In today's increasingly environmentally conscious world, traditional cleaning methods often generate large amounts of wastewater and waste, causing serious environmental pollution.

Laser cleaning technology, on the

Other hand, is a completely non-contact, non-abrasive, and pollution-free cleaning method. It does not require chemical reagents and produces no wastewater or waste residue, fully meeting the environmental protection requirements of modern industry.

By using Laser

Cleaning Machine, businesses can not only improve production efficiency but also contribute to environmental protection and achieve sustainable development.