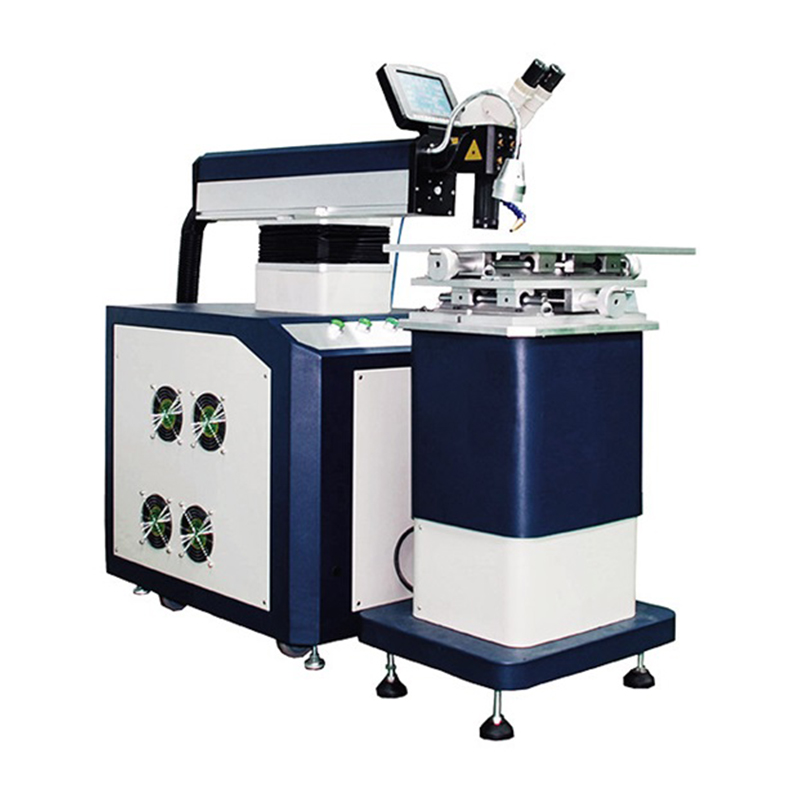

The use of laser welding fixtures in YAG Laser Mold Repair Welder to automate the production of small hardware products or spare parts is a growing trend, saving manpower and significantly improving the production capacity of

Laser Welding Machine manufacturers.

However, the design of these automated fixtures requires careful consideration of the following aspects to ensure their functionality and usability.

First, the

Fixture itself should be simple and lightweight, yet possess sufficient compressive strength and rigidity. As a fixture used in rigid-fixing processes, its relative rigidity should exceed the toughness of the workpiece being clamped.

Second, the direction and location of the clamping force should be appropriately selected. This is crucial for effective clamping. This means that the clamping operation should not disrupt the intended shape or position of the workpiece, nor cause it to move or rotate unnecessarily.

Third, the fixture should not interfere with the loading and unloading of the workpiece. The loading and unloading of welded workpieces can sometimes conflict with the clamping operation. An effective way to address this discrepancy is to modify the gripper or clamping mechanism to achieve a compromise.

When necessary, the gripper can be made removable or pipe-type to eliminate the need for lifting the workpiece.