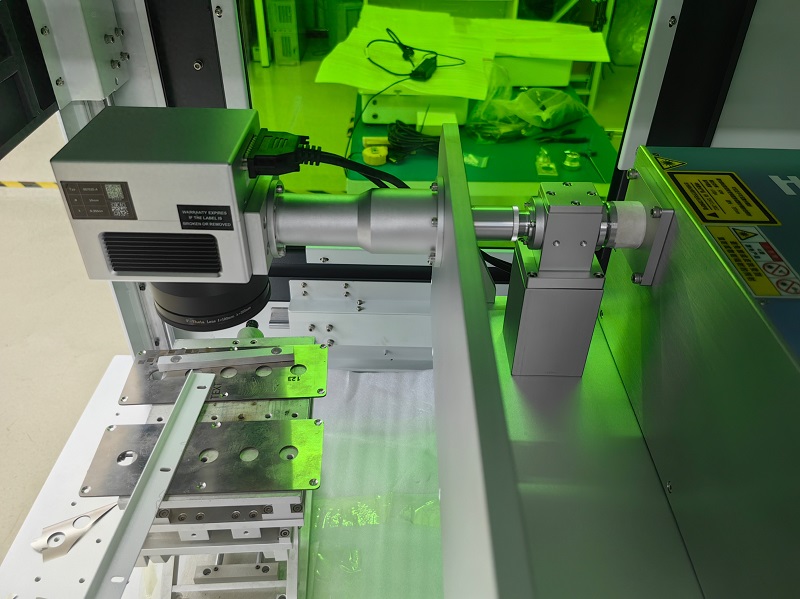

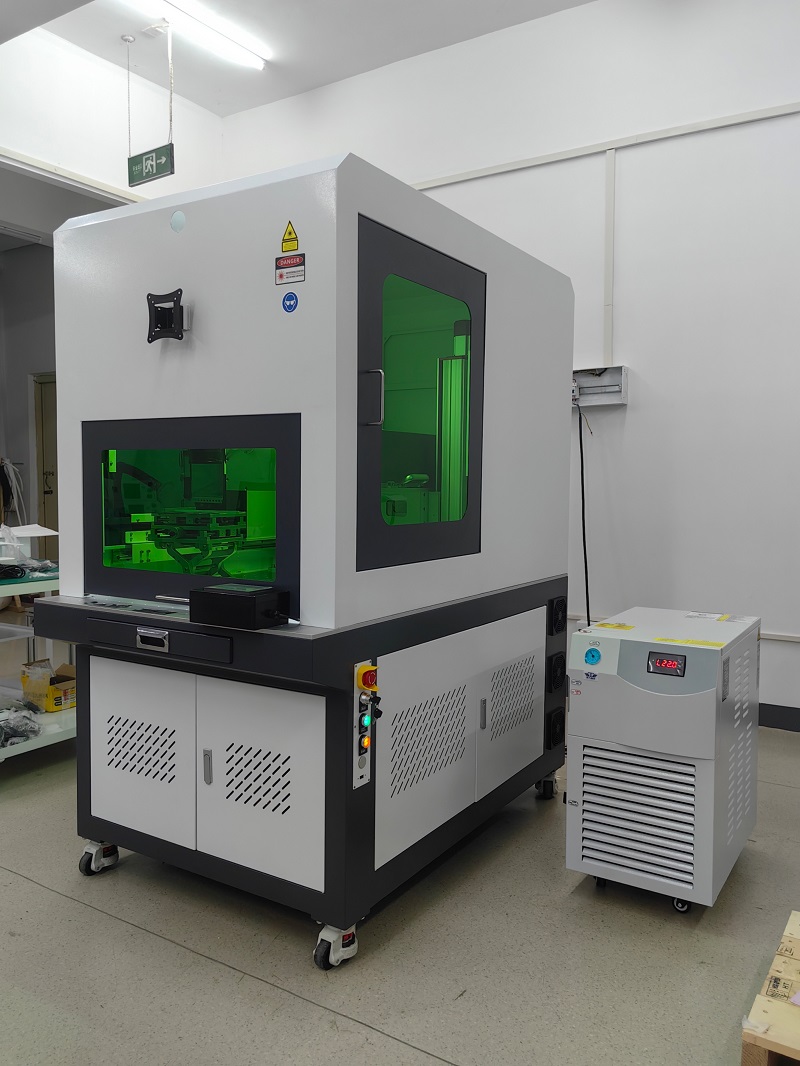

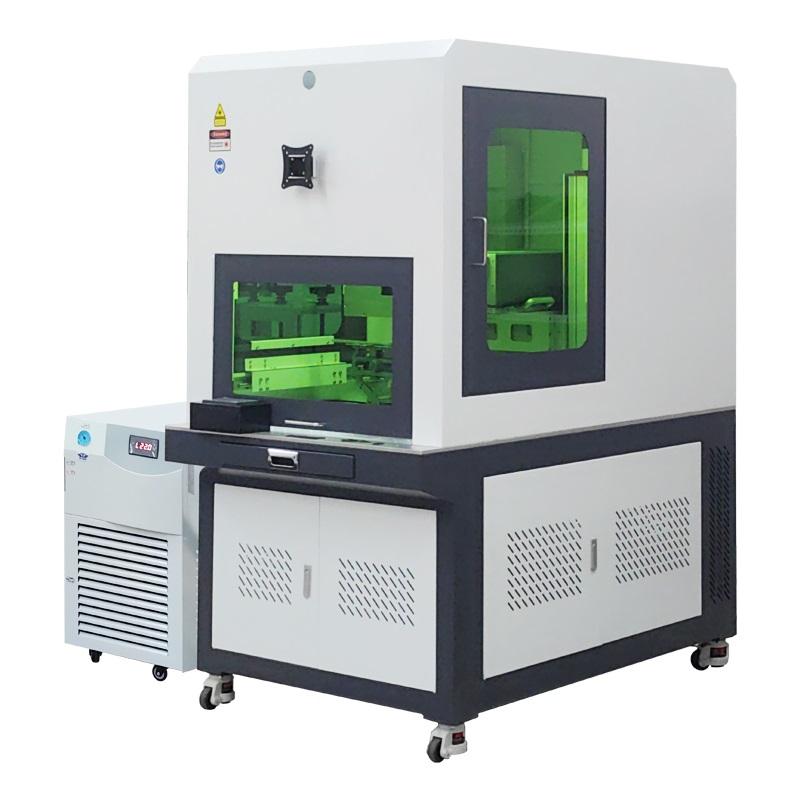

In the modern factory of the Zhongnan High-Tech Smart Port in the Beibei Park of Chongqing Science City, Chongqing Chuke Intelligent Machinery Equipment Co., Ltd. (hereinafter referred to as "Chuke Intelligent") is redefining the limits of precision machining with its newly developed CK-UVLCM-T30W UV

Picosecond Laser Cutting Machine. This machine, embodying Chuke Intelligent's decade of technological expertise, leverages the synergistic effect of picosecond ultrashort pulses and 355nm high-energy UV lasers to achieve breakthroughs in micron-level cutting accuracy and zero thermal damage, becoming a key tool for high-end manufacturing in the semiconductor, new energy, and biomedical fields.

Traditional laser cutting technology, due to its large heat-affected zone (HAZ), is prone to material deformation, melting, or thermal stress cracking, making it difficult to meet high-precision requirements. Chuke Intelligent's UV picosecond

Laser Cutting Machine solves this problem through two core technologies:

Picosecond ultrashort pulses: Single pulse duration is compressed to one trillionth of a second (10?12 seconds), releasing energy in a concentrated manner within an extremely short timeframe, instantly vaporizing the material. Heat conduction time approaches zero, and the heat-affected zone is ≤5μm, a 90% reduction compared to traditional nanosecond lasers.

355nm UV cold light source: Short-wavelength laser light is efficiently absorbed by materials, making it particularly suitable for non-metallic and composite materials. The cutting energy threshold is reduced by 40%, enabling "slag-free, burr-free" cold processing.

For example, for a top-three global glass substrate manufacturer, the yield rate for foldable screen cover cutting was only 65% with traditional mechanical cutting. Chuke Intelligent's equipment increased this rate to 98%, reduced

Consumables costs per sheet from 0.8 yuan to 0.12 yuan, and reduced the cutting line width from 50μm to 8μm, directly promoting the large-scale application of ultra-thin glass (UTG) in foldable screens. Chuke Intelligent's UV picosecond laser cutting machines have penetrated the core of high-end manufacturing:

Semiconductor sector: In 12-inch wafer cutting, the equipment utilizes femtosecond pulse synchronous control technology to achieve ultra-fine kerfs of 8μm, reducing material loss by 60% and increasing the number of wafers processed per day from 300 to 1200, meeting the needs of advanced chip packaging.

New energy sector: For lithium battery separator cutting, the equipment replaces traditional mechanical stamping with non-contact cold working, eliminating metal debris contamination and achieving a cutting speed of 5000mm/s, five times faster than traditional processes. Biomedical: In the processing of zirconia ceramic crowns, the equipment utilizes ±1μm contour control, replacing traditional CNC grinding processes and eliminating the risk of microcracks. The product has passed FDA aseptic production standard certification and has entered the global top 5 oral healthcare supply chain.

Consumer Electronics: Customized glass cover logo marking solutions for companies such as Huawei and Apple utilize third-order intracavity frequency doubling technology, resulting in a focused beam spot diameter of only 15μm and a heat-affected zone of less than 0.1mm. This effectively eliminates the dust pollution problem associated with traditional sandblasting, reducing product defect rates from 12% to 0.5%. Chuke Intelligent's breakthrough lies not only in hardware performance but also in building an intelligent ecosystem combining "laser + robotics + vision." Its digital twin system features a built-in 3D simulation module that allows for pre-production line layouts. Customers can remotely access equipment operation logs via VR, reducing fault location time to under 15 minutes. A dynamic parameter compensation algorithm uses a temperature sensor to monitor the laser cavity status in real time and automatically corrects for power fluctuations, ensuring a marking depth standard deviation of <0.005mm during 24-hour continuous operation. A cross-platform communication protocol stack includes a proprietary driver library compatible with 12 mainstream PLCs, supporting six industrial protocols including OPC UA and Modbus TCP. Device interconnection response latency is <50ms, enabling millisecond-level synchronization with heterogeneous devices such as MEXXEN barcode scanners and Siemens PLCs.

In the first half of 2025, Chuke Intelligent's overseas orders increased by 210% year-on-year, with the lithium battery industry accounting for 65%. Its clients include leading companies in the laptop and new energy sectors. In the production line of a lithium battery manufacturer in Eastern Europe, Chuke Intelligent's customized integrated

Uv Laser Marking automated production line, utilizing a three-station linkage mechanism for "marking, inspection, and sorting," achieves a 100% accuracy rate and improves overall efficiency by 300%. The client's technical director commented, "The most impressive aspect of this production line is its 'plug-and-play' capability. It perfectly replicates the inspection accuracy of MEXXEN handheld devices while increasing efficiency threefold."

Chuke Intelligent's Executive Director and General Manager, Xiao Renmin, revealed that the company plans to launch a new generation of picosecond UV lasers in 2026, further increasing frosting efficiency by 50% and expanding into superhard materials such as ceramics and sapphire. The company has already established joint intelligent inspection laboratories with several research institutes. Over the next three years, R&D investment will account for no less than 8% of revenue, with a focus on breaking through emerging technological bottlenecks in laser marking.