In July 2025, Chongqing Chuke Intelligent Machinery Equipment Co., Ltd. (hereinafter referred to as "Chuke Intelligent") announced that its independently developed new generation of high-temperature

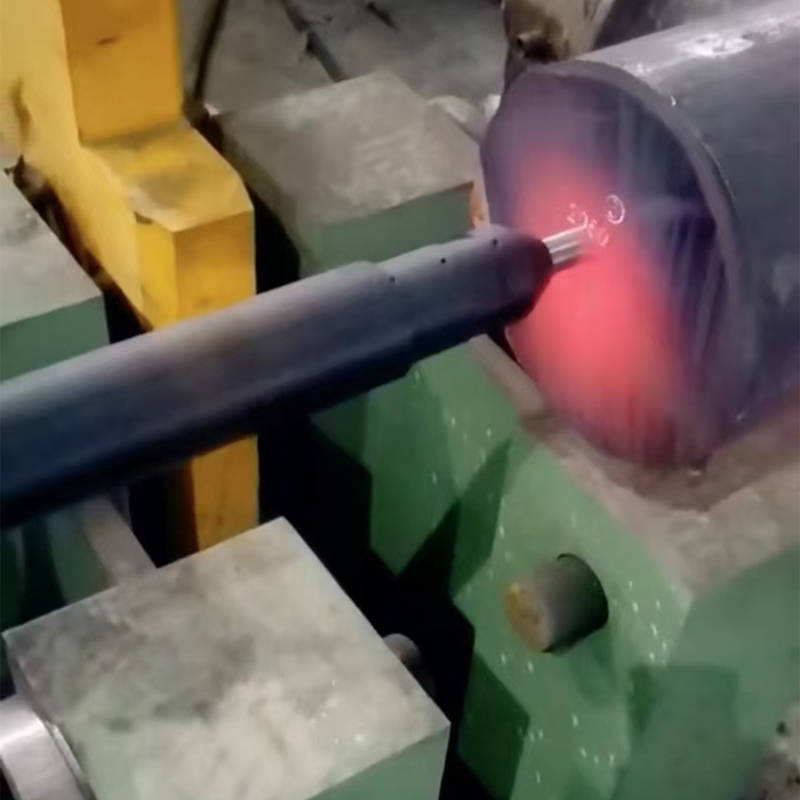

Laser Marking Machine was officially launched on the market, becoming a "key weapon" to solve the problem of high-hardness special steel marking in the global high-end manufacturing field. The equipment is designed for materials such as high-speed rail tracks, aviation wheels, and ultra-high hardness steel bars. It can directly mark at high temperatures above 600°C and integrates automated production lines to help companies achieve efficient, safe, and traceable production goals.

High-specification special steels (such as steel for high-speed rail tracks) can reach a hardness of HRC65 or above after heat treatment. Traditional pneumatic marking or scratching technology fails because it cannot penetrate the hardened layer; if the material is marked after cooling, it needs to be heated again, which is easy to cause material performance degradation. Chuke Intelligent High-Temperature Laser

Marking Machine achieves breakthroughs through three core technologies:

Ultra-high temperature adaptive

Laser Source: Using customized fiber laser with high energy density, it can directly melt the material surface at 600-900℃ red high temperature state to form a permanent mark, avoiding secondary processing after cooling.

Precise control of heat-affected zone: Through pulse width modulation and scanning speed optimization, the heat input is limited to the micron level to prevent the material from cracking due to thermal stress, ensuring that the marking clarity and material strength meet the standards.

Multi-scenario process compatibility: Supports composite processes such as paint stripping, rust removal, and micro-nano engraving to meet the stringent requirements of automotive parts, aerospace and

Other fields for marking accuracy and functionality.

Taking high-speed rail track production as an example, Chuke Intelligent Equipment can complete serial number, QR code and other markings in the high-temperature window period after the rail is extruded and before quenching. The marking depth reaches 0.1mm, the wear resistance is improved by 300%, and it is seamlessly connected with the subsequent heat treatment process, and the single-line production capacity is increased by 40%.

Chuke intelligent high-temperature laser marking machine deeply integrates the concept of Industry 4.0, and realizes full-process collaboration with the production line through modular design: it supports two-way docking with MES/PLC, can call production order data in real time, automatically generate unique identification codes, and synchronize to the quality traceability system. It is equipped with an electric precision lifting platform and a visual positioning system, which can adapt to the dynamic marking of steel parts of different sizes (such as long rails and round wheels), with a positioning accuracy of ±0.05mm. It also adopts a fully enclosed optical path and an emergency stop interlocking device, combined with a remote monitoring camera, to ensure that operators are away from high-temperature radiation areas and the risk of work-related injuries is zero.

In the production line transformation of a certain automobile wheel manufacturer, Chuke intelligent equipment is linked with a robot welding station to realize a fully automated closed loop of "welding-marking-detection", and the marking efficiency is increased from 20 pieces/hour manually to 120 pieces/hour, and the scrap rate is reduced from 5% to 0.3%, saving rework costs annually.

Chuke Intelligent High-Temperature Laser Marking Machine has passed the EU CE certification, the US FDA certification and the ISO9001 international quality system certification, and has won global orders with its excellent performance: In response to customer feedback from the Yekaterinburg Industrial Exhibition, Chuke Intelligent optimized the stability of the equipment under extreme temperature differences of -30°C to 500°C, and developed a Russian operating system to help local steel mills improve their digitalization level. In a motorcycle parts factory in Vietnam, the equipment successfully replaced the traditional inkjet printer to solve the problem of label shedding in a high-temperature oily environment, and the customer repurchase rate reached 100%. In cooperation with a German aviation company, the equipment is used for micron-level identification of titanium alloy turbine blades, meeting the requirements of the AS9100D aviation quality management system.

"The core value of high-temperature marking machines lies in 'immediacy' and 'zero defects'," said Xiao Renmin, chairman of Chuke Intelligence. "We have made Chinese equipment the 'standard configuration' of global high-end manufacturing production lines through the deep integration of laser technology and the industrial Internet." At present, Chuke Intelligence has deployed ultrafast laser marking technology research and development, and plans to launch picosecond high-temperature marking equipment in 2026 to further reduce the heat-affected zone and adapt to more sensitive materials (such as magnesium alloys and ceramic-based composites). At the same time, the company is co-building joint laboratories with many universities and scientific research institutions to explore integrated

Laser Cleaning-marking solutions and provide "turnkey" smart identification services to global customers.